Kingpan’s KS1000 TS insulated roof tile support system proved a three-fold success for the €40 million (£27.5 million) redevelopment of an historic warehouse in Custom House Quay, within the regenerated Dublin Docklands. The LPCB-approved panel system meant that architects Michael Collins & Associates could retain the building’s natural slate roof within a fire-safe specification – and it also contributed to the speed of build for main contractor, Bennett Construction.

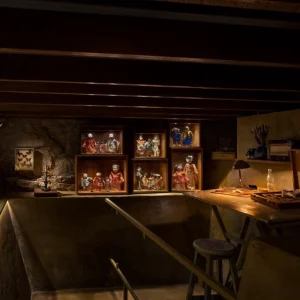

Whilst many lesser buildings were demolished during the Dockland’s regeneration, the structure of the Stack A warehouse, dating back to 1810, has been retained and transformed into a contemporary retail, dining and leisure space at the heart the new International Financial Services Centre.

The stone-built warehouse featured a 6,000m2 natural slate roof that was stripped to allow the installation of Kingspan’s thermally insulated KS1000 TS slate and tile support system. The pre-engineered system provides a single-fix platform onto which the timber roof battens are fitted, streamlining site work and speeding the completion of a weathertight shell. Whilst the roof was being re-slated, using many of the original slates to maintain the building’s historic appearance, internal fit out was already underway.

In use, the Part L2-compliant (Part J – Scotland) system provides U-values down to 0.20W/m2K* from six PIR-core options ranging between 40 and 100mm-thickness. By eliminating most of the air leakage associated with conventional built-up insulation, sarking and roofing felt, the KS1000 TS system can reduce the occupant’s M&E plant and energy operating costs by up to a third.

KS1000 TS panels are fire-safety rated as a Class 1 surface for spread of flame to BS 476: Part 7: 1987 and have LPCB approval to LPS 1181 for buildings in the UK, the category officially recognised by the Association of British Insurers for use within a non-combustible fire-safety specification – with no premium loading for the building owner.

KS1000 TS has a lifetime durability of up to 25 years to first maintenance and the overall life expectancy is 40 years.

* To achieve 0.20W/m2K, a core depth of 100mm is required.